As someone who has worked closely with industrial welding equipment for years, I can confidently say Roclas' 1500W Laser Welding Machine represents a breakthrough in metal joining technology. Let me walk you through why this system stands out in today's competitive market.

Core Technical Specifications

The machine's 1500W laser power with 220V power supply delivers exceptional energy efficiency. Operating at 1080±5nm wavelength, it achieves remarkable beam quality for precise heat input control. What impresses me most is its dual working modes – both continuous and modulation welding – allowing adaptation to different material thicknesses (0-3mm gaps) and types including stainless steel, aluminum, copper alloys, and precious metals.

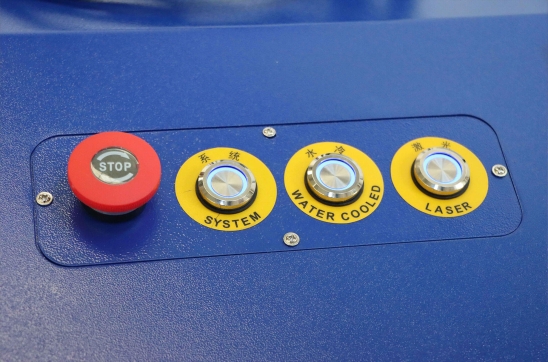

With welding speeds of 0.7-2.0m/min, it maintains consistent performance across challenging environments (-5℃ to 35℃ ambient temperature, <70% humidity). The water-cooling system ensures thermal stability during prolonged operations, while the dedicated handheld welding OS offers intuitive control.

Unmatched Reliability

Having examined numerous welding systems, I appreciate Roclas' industrial-grade construction:

Heavy-duty steel structure processed by CNC five-face machining centers

Premium components from Schneider (France), SMC (Japan), and German cable systems

Imported servo drives and reducers ensuring motion precision

The ≥6KW overall power supports stable operation across its 0-2000W adjustable range, making it versatile for both delicate jewelry welding and heavy industrial applications.

After-Sales Assurance

Roclas backs this machine with exceptional support:

1-year comprehensive warranty (consumables excluded)

Lifetime maintenance with 24/7 English-speaking technicians

Free replacement for non-artificial damages during warranty

Cost-price post-warranty repairs

Full compliance with CE, FDA, and SGS certifications

Practical Advantages

From my observations, users particularly value:

Burr-free results requiring minimal post-processing

Multi-material capability eliminating machine changeovers

Energy efficiency reducing operational costs

Compact footprint saving workshop space

Customized Solutions

When requesting a quote, provide these details for optimal configuration:

Primary materials (sheets, pipes, or both)

Maximum dimensions of workpieces

Intended applications (automotive, aerospace, etc.)

Your port location for logistics planning

Why Roclas Stands Out

After visiting their facility, I understood their 15+ years of R&D translates to:

Patented laser modulation technology

Rigorous quality control (ISO9001 certified)

Global export experience across 30+ countries

Direct manufacturer pricing without middlemen

Final Recommendation

For businesses seeking a reliable, high-precision welding solution, the Roclas 1500W system offers outstanding value. Its combination of German-engineered components, Japanese motion systems, and French electrical parts creates a truly world-class machine.

Should you need further technical details or wish to discuss specific applications, their multilingual team provides responsive consultation without sales pressure. The verification process for quotations is straightforward, and they accommodate various communication channels (Skype, WhatsApp, etc.) for international clients.

This machine particularly shines in automotive part fabrication, jewelry manufacturing, and precision instrument repair – essentially any application demanding clean, strong welds with minimal heat distortion. Considering its competitive pricing against European counterparts and robust after-sales network, it's a prudent long-term investment for serious manufacturers.

(This promotional article is not intended as a technical document. For product details, please consult the pre-sales engineer. We will serve you wholeheartedly. Your satisfaction is our continuous pursuit.)

Függetlenül attól, hogy általános tanácsra vagy konkrét támogatásra van szüksége, örömmel segítünk Önnek.